nanosized powders production system NanoEx

Electrical explosion of wires (EEW) is a highly-energized method for production of metallic, oxide, nitride and carbide nanopowders. The method is carried out by passing of a short powerful high-density current pulse through the material produced in the form of wire. When the current pulse passes through, the temperature of the wire material raises above the boiling point and is dispersed in a burst. The generated vapor expands in a shockwave manner, followed by superfast cooling and condensation processes resulting in formation of very small particles under 30 nm in diameter. Crystal Technologies s.r.o. produces and offers for sale NanoEx, a system for nanopowder synthesis by the EEW method.

The NanoEx System is an advanced cost-effective solution, a product resulting from many years of scientific and engineering work aimed at enhancement of hardware implementation of the EEW method. The NanoEx System includes all the latest updates of the production process in accordance with the most recent requirements to nanopowders due to the new fields of their application. Electrical explosion of wire offers the lowest energy intensity among all other physical methods for nanopowder production. Moreover, the EEW allows setting up a production unit with a capacity of up to several kilograms per day at a small-area facility. We can offer the design, manufacture and installation of the equipment system for the complete nanopowder production cycle of a requested capacity, from wire processing to finished product packaging.

The NanoEx System allows obtaining the following types of nanopowders:

> Pure metal nanopowders;

> Oxide / carbide / nitride under an oxygen atmosphere / carbohydrates / nitrogen (ammonia) nanopowders, respectively;

> Intermetallic nanopowders.

Characteristics of the nanopowders

Mean particle size D50% |

from 30 to 500 nm depending on the material and process parameters |

Particle size distribution |

log-normal |

Deviation rate |

controlled, depending on the duration and intensity of the current pulse. |

Specific surface area |

0.5 - 20 m2/g |

Chemical purity |

Up to 99.9+ % |

Bulk density |

0.05 – 0.2 g/cm3 |

Particle shape |

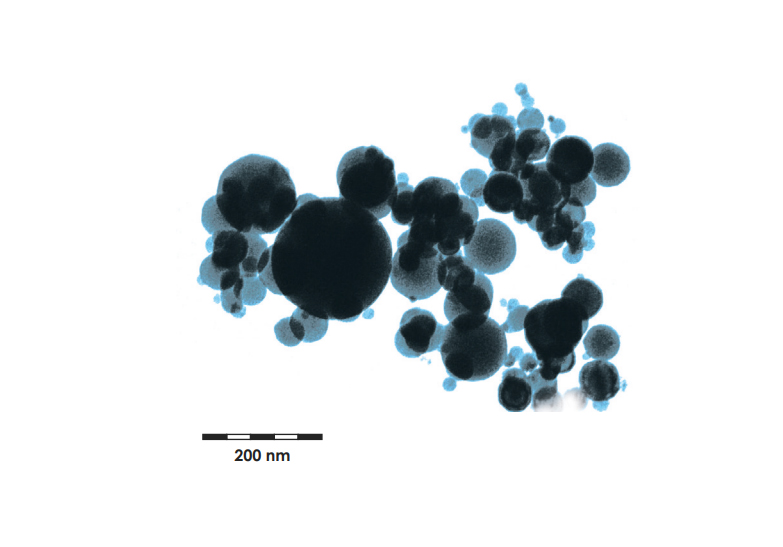

spherical |

Output rating for some materials |

Al / Ti / Mg: up to 120 g/hour Ni /Co: up to 220 g/hour W / Cu / Ag: up to 340 g/hour |

Unique properties of nanopowders

> Low sintering temperature; e.g., silver nanopowder of fine fraction may sinter already at room temperature.

> Stability of electrophysical properties at low temperatures.

> Availability of excessive stored energy.

> Ability to readily form various intermetallic compounds even at low temperatures.

> High reactivity, increasing manifold at the temperatures of up to 200 - 500 °С.

> High electromagnetic radiation absorption coefficient across a broad wave spectrum.

Additional options

Two-stage separator

The nanopowder obtained by the electrical explosion method contains a minor amount of particles of a considerably bigger size than the base fraction (10 mkm). An additional separation step allows automatically removing these particles even at the production stage.

Reduced dead volume

When the system is started, a certain amount of the nanopowder dust fills the internal surfaces of the internal surfaces of the system (dead volume). For standard system size the weight of nanopowder spent on to the dusting may amount to 200 g. In order to reduce this loss, we offer a special version of the system with a reduced dead volume.

Liquid nitrogen cooling

system One of the important features of the nanopowders prepared using the exploding wire method, is a low sintering temperature. The temperature in the working chamber of the unit at the time of electrical explosion can be as high as 10 000 K. For quick cooling of the gas mixture coming from the reactor, all the electrical explosion units are normally equipped with a freon cooling system in order to prevent sintering of the finished products. In case of certain materials and operating modes, the freon cooling system does not provide sufficient cooling as to prevent product sintering, therefore, an additional liquid nitrogen cooling system is recommended.Nanopowder application

nanopowders application:

> catalysts;

> hydrogen energetics, hydrogen production; > fuel cell manufacturing;> electronic components manufacturing;

> modification of varnishes and paints;> modification of polymers, attribution of conductivity to polymers;

> use of nanopowders as sintering activators;> attribution of antibacterial properties to the materials used in medicine;

> composite materials with specific properties;… and much more!

TECHNICAL SPECIFICATION:

| Current pulse parameter control range | |

Charging voltage |

15 – 35 kV |

Pulse duration |

2 – 6 µs |

Current density |

104 – 106 А·mm-2 | Working chamber atmosphere |

Working pressure in the chamber |

10-2 Pa – 0,5 MPa |

Working gas temperature |

25 – 60 0 С |

Working gases |

Air, CO2, Ar, N2, O2, NH3 and others | Initial wire |

Wire diameter, mm |

0,1 – 0,6 mm |

Wire length |

50 – 160 mm | Finished product parameters |

Mean particle diameter d50% |

from 30 to 500 nm depending on the material and process parameters |

Particle size distribution |

log-normal |

Deviation rate |

controlled, depending on the duration and intensity of the current pulse. |

Specific surface area |

0.5 – 20 m2/g |

Chemical purity |

Up to 99.9+ % |

Bulk density |

0.05 – 0.2 g/cm3 |

Particle shape |

Spherical |

Output rating for some materials |

For Al / Ti / Mg: up to 120 g/hour For Ni /Co: up to 220 g/hour For W / Cu / Ag: up to 340 g/hour | General parameters |

Operating mode |

Semi-automatic |

Cooling system |

Freon. Option: Liquid nitrogen |

Electrical explosion initiation |

Forced |

Continuous work time |

At least 3 h |

Power consumption |

max 5 kW |

Power supply voltage |

380 V, 50 Hz, 3 phases |

Dimensions |

Main module does not exceed 2500х2500х2500 mm Control module does not exceed 500x600x1500 mm |

Weight |

max 500 kg |